Overview

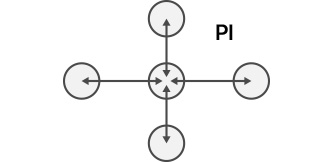

Test Flow.

- Request

- Incoming Inspection

- Test

- Outgoing Inspection

- Packing

- Shipping

Test Web Report (Real-time monitoring)

Wafer Test Flow.

-

Incoming Incoming

- ·Visual and AVI

-

Probe Test Probe Test

- ·Electrical test

- ·Hot/Cold test

- ·Function test

-

Option

Inking/bake Inking/bake

-

Outgoing inspection

- ·Visual and AVI

-

Packing and Shipping

Final Test Flow.

-

Incoming Incoming

- ·Visual

-

Package Test Package Test

- ·Electrical Test

- ·Hot/Cold test

-

Option

Quality Electrical Test

- ·Sampling inspection

-

Baking Baking

- ·Moisture Removal Process

- ·Skip the baking process based on the type of packaging

-

Option

Visaul Inspection

- ·Foreign material, Crack check

-

Outgoing inspection

- ·LIS

-

Option

Tape & Reel Process

- ·According to shipping method

-

Packing and Shipping

Engineering Service.

-

Engineering Support Including Test Program Development

-

Consultation on Test Configuration for Various Products and Locations

-

Engineering Services Including Analysis of Defects and Characteristics Specific to Products

-

Wide range of tester platforms

Competitive Advantage.

Technology owned by the company

Application

GMTest offers comprehensive solutions for a wide range of package tests, including Mixed & RF Test, Broad Band, Wireless/Mobile, RF/Analog, and Digital consumer. We are equipped to test devices across various functions, sizes, and types. Leveraging our extensive technological expertise, we deliver all the test engineering services our customers need, such as Test Plan & Test Program Development, and Hardware Design for prototype testing.

- SYSTEM IC

-

- # MCU

- # SoC

- # Custom IC

- # DSP, ISP

- # AI

- # Audio

- IoT & Sensor

-

- # Controller

- # MCU

- # Security

- # Touch Sensor

- # Memory

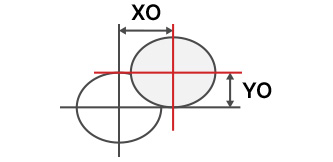

Wafer Test

Additionally, GMTest provides Wafer Probe Test and Bumped Wafer Cold Test capabilities. With our rich technological background, we offer comprehensive test engineering services, including the development of test plans and programs, as well as prototype hardware design and testing.

Tester

| Model | Maker | Specification | Option |

|---|---|---|---|

| Micro Flex | Teradyne | Digital, DC, Mixed | HSD200 / DC30 / DC75 / DC80 / DC90 / BBAC |

| Integra Flex | Teradyne | Digital, DC, Mixed | HSD200 / DC30 / DC75 / DC80 / DC90 / BBAC |

| Uflex | Teradyne | Digital, DC, Mixed | UP1600 / UVI80 / DC80 / UPAC80 |

| Verigy93K | Advantest | Digital, DC, Mixed | PS800 / PS1600 / MSDPS / AVI64 / VI32 / MCA / MCB |

| T2000 LSMF | Advantest | Digital, DC, Mixed | DM800MHZ / PMU32 / DPS500mA / LCDPS / AAWGD / BBWGD / JMM / RC5V |

| T2000 MSMF | Advantest | Digital, DC | DM125MHZ / DPS500mA / LCDPS / HCDPS |

| ETS-364 | Teradyne | Digital, PMIC | SPU-100, APU-12,DPU-16,QMS,QTMU |

PROBER

| Other equipment | Specification |

|---|---|

| PROBER | 8" ~ 12" Option, Hot & Cold Option |

| AVI | 8" ~ 12" Wafer AVI |

Final Test

Tester

| Model | Maker | Specification | Option |

|---|---|---|---|

| Integra Flex | Teradyne | Digital, DC, Mixed | HSD200 / DC30 / DC75 / BBAC / VHFAC |

| Micro Flex | Teradyne | Digital, DC | HSD200 / DC30 |

| J750 | Teradyne | Digital, DC | HSD100 / HSD200 / APMU |

| Verigy93K | Advantest | Digital, DC, Mixed | PS800 / PS1600 / PS9G / MCA / MCB / VI32 / MSDPS / DPS64 |

| T2K-IPS(Non-EPP) | Advantest | Digital, PMIC | DM250Mbps, DM800Mbps, MMXH, MFHP |

| T2K-IPS(EPP) | Advantest | Digital, PMIC | 1GDMbps, MFHP, GVI64 |

| ETS-364 | Teradyne | Digital, PMIC | SPU-100, APU-12, DPU-16, QMS, QTMU |

HANDLER

| Other equipment | Specification |

|---|---|

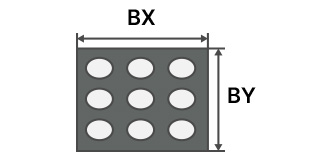

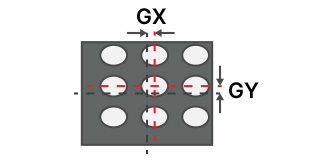

| Horizontal Handler | - In / Out Arm : 4Hands Or 8Hands - Temp Range : -55 ~ 130 ℃ |

| Turret Handler | - Test : Max 8PARA - Visual Inspection (2D, 3D) - Tape & Real : QFN / MLF (1x1 ~ ) |

Back End

LIS Process

- ·Lead Inspection System

- ·The process involves determining the quantity and identifying defects, as well as sorting quality chips that passed the final test by examining their external condition.

- ·Items subject to inspection

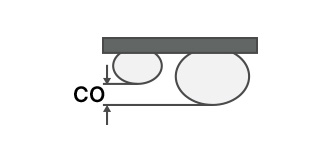

- Ball Pitch

- Ball Offset

- Ball Width

- Ball Quality

- Body Dimensions

- Grid-to-Package Offests

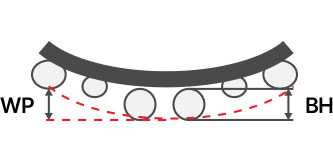

- Ball Coplanarity

- Warpage

- Ball Height

T&R

- ·Tape & Reel

- ·The process involves drying chips that have passed the visual inspection in a bake oven for a designated period specific to each product, and then packaging them in carrier tape.

- ·Input supplementary Materials

Packing

- ·Vacuum packing, Small Box

- ·The process involves final shipment preparation by packaging according to customer-specified packaging specifications, divided into Tape & Reel or Tray Type.

- ·The process includes placing materials, Hi Card, and Desspak in an A/L Bag as per customer standards and then vacuum-sealing them using equipment.

FGS Process

- ·Finished Good Store

- ·Store items that have finished inner box packaging and prepare the outer box.

- ·Store items with completed outer box packaging and dispatch them according to customer orders.